Where To Find A Reliable Tyre Pyrolysis Plant For Sale

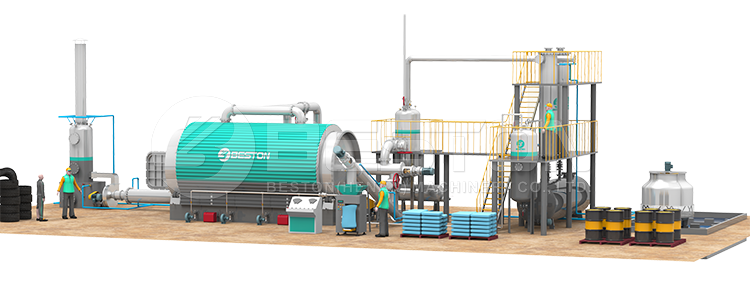

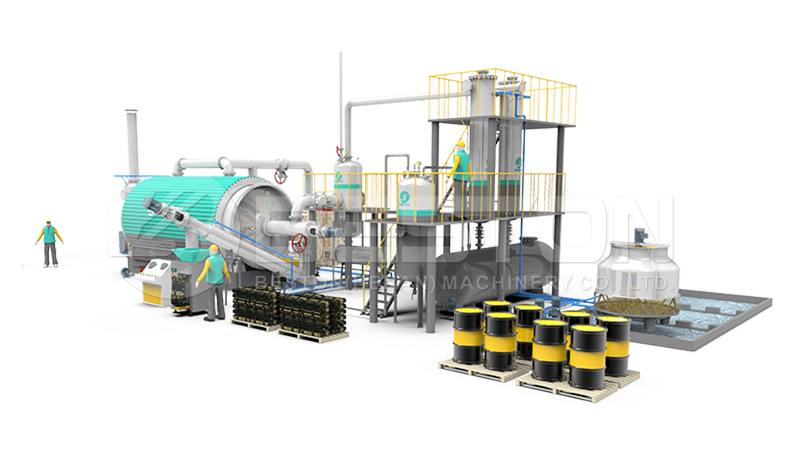

Recycling can be an extremely lucrative business. You can help people in your local community get rid of things they don’t need anymore and offer them in return some new products that they need. This is the basic principle of recycling. Waste tyre is one of the best resources you can use, as you can turn it into fuel. All that you need is to find the top pyrolysis plant and a suitable tyre recycling business plan.

If you’re looking for a tyre pyrolysis plant for sale, you’ll need to put your research skills and your negotiations abilities to good use. Find out how to search for this type of equipment online, and what to look for in a reliable supplier. Use the tips in this article to make the right purchase for your business and also you can get a suitable tyre recycling business plan.

The internet is perhaps the best place to look for such tyre pyrolysis plant for sale. Just use whatever search engine you want. You’ll get dozens of results within a few seconds. The biggest challenge isn’t to find suppliers, but to know which are the truly reliable ones. Your goal should be to select a reliable manufacturer, experienced and able to live up to your expectations. In order to do this, you’ll need to start by checking out their experience and their work background. Furthermore, you’ll have to make sure they do have the right tire recycling machine for sale. In case you don’t find it on their website, contact them to ask for their full inventory list.

Don’t be afraid to buy from sellers from other countries. You may find lots of China manufacturers of such equipment in various trading and business directories. They are able and willing to work with customers like you, so you can rest assured they are going to deliver the quality you expect. However, before making your final choice, consider checking some of their client references. You may have to send a message to these suppliers to ask for the contact details to find the best tire recycling machine. Do it, because it will be time well spent. You’ll have the opportunity to find out what to expect from these manufacturers directly from their customers. This is as good as it gets, as you won’t find these details anywhere else on the web.

It matters less where you’ve found these suppliers, as long as you’ve narrowed down your list in accordance with your specific selection criteria. Don’t compromise on quality for the sake of a lower price. Always try to negotiate a better deal, but not by agreeing to poor quality services or equipment. You need a reliable machine to serve you for a very long time, and to enable you to stick to your own deadlines. One of the goals of your waste tyre recycling business should be to keep your clients satisfied by delivering them their orders as agreed. Beston Group will be a good choice for you.

If you follow the above tips, you’ll surely find the type of equipment you need, and a reliable contractor to guide you throughout the installation process. More information can be known from the Beston sales consulting service. Get pyrolysis plant cost here.