How Do Tire Pyrolysis Recycling Systems Work

Recycling is an essential practice for the simple reason that it relieves our environment of the non-biodegradable wastes that seem to be littered all over or for the fact that is results into raw materials that form the intermediate products for other industrial processes. It is for these and many more other reasons that efforts are being undertaken all over the world to recycle both domestic and industrial waste products. This is why there was a need to have tire recycling systems that takes care of everything.

In this article we focus on one recycling process that is able to achieve 100% efficiency in that the end products of the process are directly usable or can undergo further processing to obtain more usable products. The process is referred to as tire pyrolysis and as the name suggests it is used to recycle tires. Tires are apparently the largest and most problematic wastes to get rid of. This is of course before the invention of tire pyrolysis as we shall shortly discover. Here to know the cost: https://tyrepyrolysisplants.net/tire-recycling-plant-cost.html.

The problematic nature of tires is attributed to their durability, production in large volumes, and their non-biodegradable nature. In the 80s and 90s, it was estimated that around 260 million tires were being discarded annually. This figure has probably doubled or even tripled considering the increased number of people who own cars, bicycles, and motorbikes.

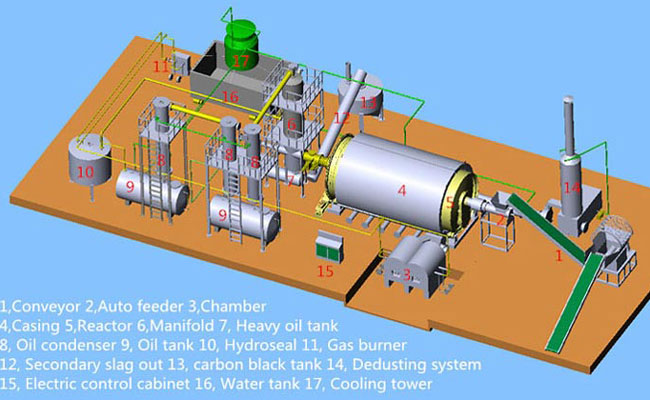

A tire recycling machine is one that involves the heating of shredded or whole tires in an oxygen-free chamber. The shredded or whole tires are softened in the reaction chamber causing the disintegration of rubber polymers into smaller molecules. Due to their small size, the small molecules can very easily evaporate and escape the reactor.

The escaping vapors can be burned directly to produce the energy required to sustain the pyrolysis process or any other industrial process. The gases can also be condensed in a cooling chamber to form an oily fluid that is often used as fuel. Molecules that are too tiny to condense are utilized in their gaseous form as fuel. About 40% of the tire composition is typically made up of mineral elements that are extracted from the process in solid form. We, Beston Machinery, are the leading waste tyre recycling plant manufacturer in China. And we provide superior after-sales service.

When this process is carried out as recommended, there are no emissions or wastes associated with it. But it is worth noting that the properties of the gas, solid, and liquid output are determined directly by the type of feedstock used for the process as well as the conditions surrounding the process. For example, when the process is carried out using whole tires, fibers and steel should be expected in the chamber and as such measures have to be taken to extract them. The energy used to decompose rubber in the process includes energy from electrical induction, directly fired fuel as well as microwave energy.

If you want to buy high quality waste tire recycling pyrolysis systems, please go to this site tyrepyrolysisplants.net.