Steel Bar Cutting Machines Can Be Used For Many Different Applications

Throughout the centuries, people have employed a variety of different techniques for cutting metal bars. In the past, this usually involved traditional metalworking techniques. Today, however, steel bar cutting machines are used in industrial applications to make the process of cutting through even the thickest steel bars much quicker and easier.

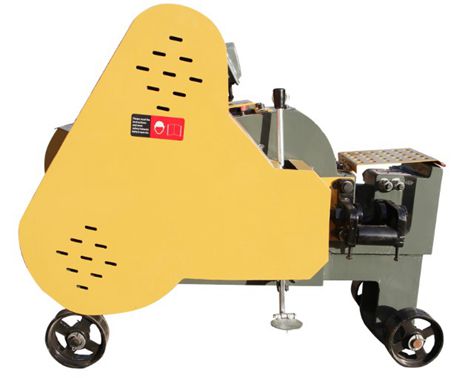

These machines can vary significantly in terms of their design. Generally, different types of machines are best suited to different purposes. For instance, small, hand-held machines are often used on job sites to cut rebar. Larger, automatic machines, on the other hand, are typically used in shops and warehouses since they are capable of cutting large volumes of steel bars in very little time.

Steel bar cutters are commonly used in the construction industry. When workers pour concrete for foundations or other structural elements, the concrete is reinforced with pieces of steel rebar. This rebar needs to be cut to precise lengths in order to provide the proper level of support.

For small projects, construction workers take portable steel rebar cutters to the job site and cut the rebar on site. For larger projects, on the other hand, all of the rebar may be cut ahead of time in a factory or warehouse using a large, automatic bar cutter. This can help save time during the construction process.

Although these bar cutting machines can be purchased by individual construction companies, they are also often used by building supply companies. These companies cut large volumes of rebar into specific lengths for resale to the construction industry. Typically, these companies order large coils of steel bar directly from the foundry. They then cut different lengths of the bar off of the large coil to resell to their customers.

In these types of high-production environments, automatic bar cutting machines http://rebarprocessingequipment.com/steel-bar-cutting-machine/ are absolutely essential. Trying to make so many cuts with a manual machine would be far too time-consuming and would eat away at any profits that the company might make. With an automatic machine, on the other hand, the cutting is done quickly and precisely, allowing them to turn a nice profit when it comes time to resell the pre-cut lengths of rebar.

This article barely scratches the surface of the many different applications that there are for steel bar cutting machines. Any company that regularly works with rebar or other types of steel bars can benefit from the use of one of these machines.

Automatic machines are best for environments where speed is essential. They make it possible to cut extremely high volumes of steel bars to specific lengths in very little time.

Manual cutting machines, on the other hand, are a good choice for companies that deal in lower volumes or that need to be able to cut rebar on location. Oftentimes, these machines of Ellsen are small enough to be easily transported from one location to another. This makes it possible to use them on the job site, allowing workers to cut pieces of rebar to the correct length as they work on the project.

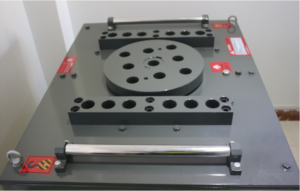

In conclusion, TMT bar bending machines have a very long operational life, which makes them a top choice with those that are looking for used equipment. They are built to be sturdy, highly functional, and use a very low amount of power yet still provide the best results. After you have looked at this particular machine, and have read reviews online about how this works, you should be able to choose one without any problem. They are designed to last, and due to the affordable pricing associated with these bar bending machines, even the smallest construction companies can afford to purchase one of these highly coveted bar bending units. Do a search today and you will quickly find many of these for sale that you can purchase for your company right away. As a specialized supplier with good reputation, Ellsen provides excellent TMT bar benders for sale. Click here:

In conclusion, TMT bar bending machines have a very long operational life, which makes them a top choice with those that are looking for used equipment. They are built to be sturdy, highly functional, and use a very low amount of power yet still provide the best results. After you have looked at this particular machine, and have read reviews online about how this works, you should be able to choose one without any problem. They are designed to last, and due to the affordable pricing associated with these bar bending machines, even the smallest construction companies can afford to purchase one of these highly coveted bar bending units. Do a search today and you will quickly find many of these for sale that you can purchase for your company right away. As a specialized supplier with good reputation, Ellsen provides excellent TMT bar benders for sale. Click here: