How To Make Pellets From Woods

Pellets from wood can be used for several purposes. They can be used as a material for animal bedding, as fuel and for some types of grills and barbecues. The pellets can be used in cooking stoves as they produce more heating hence making temperatures rise quickly. So you need a wood pellet making machine, then you will know how to make wood pellets from woods.

In most cases, industrial wood pellet mills are used to make wood pellets in bulk quantities. However, did you know that you can make your own pellets? All you have to do is to reduce the raw materials into pieces that are very small and then compress then into dense pellets. Do you want to make pellets of wood? If the answer is a big yes, then read on to find out more.

Step 1: Gather the wood you will use

The first step is gathering the wood pieces you will be using and then reduce their sizes. Shred or chip the raw materials until there are no pieces that are larger than 2.5 cm (1inch). Reduce the size of the wood further using a hammer mill. Make the pieces as small as possible without turning them into sawdust. If your project is not very big, you can choose a small wood pellet mill for sale.

Step 2: Dry the material

Use heat to dry the material. Content moisture needs to be between 10 and 20%. You can either choose to let the wood dry in the sun or you can use an industrial slow heating oven. However, if your raw materials are sawdusts, you can choose a sawdust pellet machine, these are sawdust pellet mill manufacturers, you can have a look.

Step 3: Pour the wood material into a batch mixer

Doing this ensures that all the pieces of wood are consistent and uniform in terms of density, size, and moisture. Ensure that there is an agitator or rolling drum working with the batch mixer.

Step 4: Produce your pellets

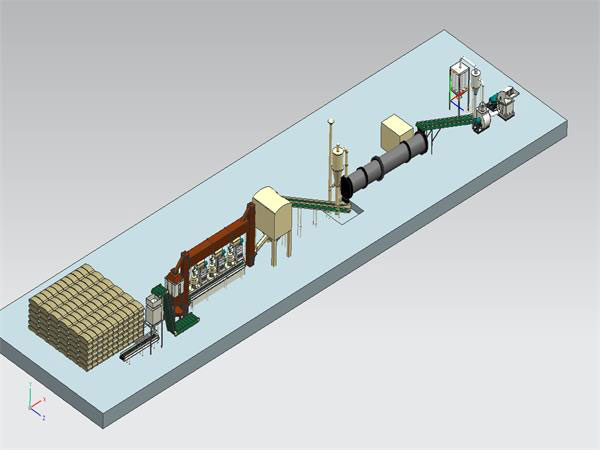

You can use a pellet mill to produce pellets or use a pallet press which has a die and roller in case you are going to produce smaller batches. The die is a metal piece that has holes drilled through it. The roller typically goes across the die and will press the wood through the holes into pieces that will have the same size as the finished wood pellets. If you want to produce wood pellets, you can choose a wood pellet making line, which will help you produce quality pellets. Pellet presses are usually round die or flat die. The two types of presses can make pellets that are consistent in terms of moisture level and density.

Step 5: Sieve improperly formed pellets

During the pressing process, some of the pieces will break or fall apart. Therefore, it is good to separate the pieces that are not formed properly. You can do this by shaking or sifting the pieces through a screen. If you want to learn more about pellet machine, you can see this page: https://www.facebook.com/Beston-Pellet-Machine-379875249096537/.

Step 6: Cool the pellets thoroughly

Pellets coming out of a pellet press are usually hot and moist. This is why it is a good idea to ensure that they are dry and cooled before packaging them. You can make the pellets cool and dry by spreading them and leaving them to cool and dry naturally. If you have a large quantity of rice husks, you can choose a rice husk pellet making machine for sale, which is very cost-saving. Learn more here about rice husk briquette machine price.

Step 7: Bag and store your pellets

The best plastic bags for storing pellets are those that are not too big to an extent that they can’t be transported. Once you have put the pellets in the plastic bags, seal the bags and store them in a cool, dry place where they will not become moist. Beston group is a reliable and reputable pellet machine supplier, if you want to get a quality pellet machine, you can have a look.